Structure and Features

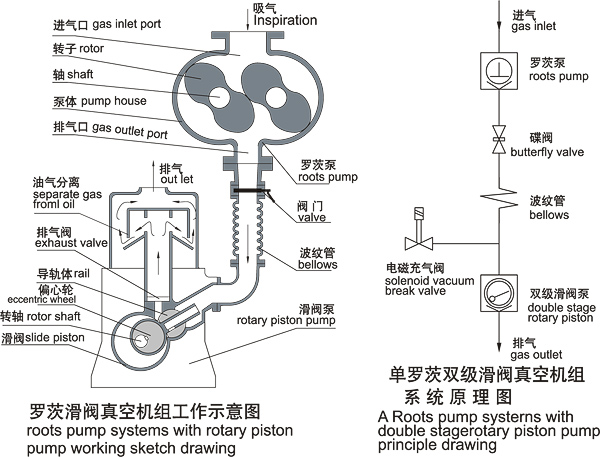

Roots pump is used as main chief pumps, rotary piston pump is as backing pump. They are connected in series. By the vacuum electric relay and electricity trigger manometer, roots pump and rotary piston pumps own some features of start and stop automatically, automatic protective overload function. The system is installed on the chassis. Equip pipe, valve, electric control box, cooling water pipe,

According as cubage of the pumped system and the ultimate pressure, the ratio of the nominal pumping speed between the pump and other pump is the range between 4:1 and 10:1. The front is suitable for bigger vacuum system and operated for long time with the lower inlet pressure or ultimate pressure. In order to preventing that the oil return to the system, it is equipped an electromagnetic vacuum break valve on the gas inlet pipe of the rotary piston pump. Its action and the motor of rotary piston pump carry out linkage. When the rotary piston pump is stopped, solenoid vacuum break valve charge the inlet port of pump with gas, ensure oil return to oil box from the pump housing and avoid vacuum oil polluting vacuum system.

There are designs as follow according as different ultimate pressure.

●A Roots pump systems with single stage rotary piston pump

●A Roots pump systems with double stage rotary piston pump

●Two Roots pump systems with single stage rotary piston pump

●Two Roots pump systems with double stage rotary piston pump

Use:

Roots pump systems with rotary piston pumps have features of obvious effect of saving energy, high vacuum and high pumping speed in high vacuum. It is widely used for transformer and electrical wire of electric utility industry, vacuum soaking and vacuum drying of capacitor. It is a perfect vacuum equipment of vacuum coating,vacuum smelting, vacuum heat treatment, vacuum filtering oil, vacuum cooling and drying. If it is used for pumping the gases mixed with a little vapour and dust, it is necessary that a filter is fitted in the gas inlet pipe.

Roots pump is used as main chief pumps, rotary piston pump is as backing pump. They are connected in series. By the vacuum electric relay and electricity trigger manometer, roots pump and rotary piston pumps own some features of start and stop automatically, automatic protective overload function. The system is installed on the chassis. Equip pipe, valve, electric control box, cooling water pipe,

According as cubage of the pumped system and the ultimate pressure, the ratio of the nominal pumping speed between the pump and other pump is the range between 4:1 and 10:1. The front is suitable for bigger vacuum system and operated for long time with the lower inlet pressure or ultimate pressure. In order to preventing that the oil return to the system, it is equipped an electromagnetic vacuum break valve on the gas inlet pipe of the rotary piston pump. Its action and the motor of rotary piston pump carry out linkage. When the rotary piston pump is stopped, solenoid vacuum break valve charge the inlet port of pump with gas, ensure oil return to oil box from the pump housing and avoid vacuum oil polluting vacuum system.

There are designs as follow according as different ultimate pressure.

●A Roots pump systems with single stage rotary piston pump

●A Roots pump systems with double stage rotary piston pump

●Two Roots pump systems with single stage rotary piston pump

●Two Roots pump systems with double stage rotary piston pump

Use:

Roots pump systems with rotary piston pumps have features of obvious effect of saving energy, high vacuum and high pumping speed in high vacuum. It is widely used for transformer and electrical wire of electric utility industry, vacuum soaking and vacuum drying of capacitor. It is a perfect vacuum equipment of vacuum coating,vacuum smelting, vacuum heat treatment, vacuum filtering oil, vacuum cooling and drying. If it is used for pumping the gases mixed with a little vapour and dust, it is necessary that a filter is fitted in the gas inlet pipe.

單羅茨雙級(jí)滑閥真空機(jī)組主要性能參數(shù)表

| 機(jī)組型號(hào) | 泵型號(hào) | 極限壓力 | 抽氣速率 | 進(jìn)氣口徑 | 排氣口徑 | 電機(jī)功率 | ||

| 主泵 | 前級(jí)泵 | Pa | L/s | mm | mm | Kw | ||

| JZJ(P)2H70-8 | ZJ(P)70 | 2H8 | 2x10-2 | 70 | 80 | 32 | 1.5 | 1.1 |

| JZJ(P)2H70-5 | ZJ(P)70 | 2H15 | 2x10-2 | 70 | 80 | 32 | 1.5 | 2.2 |

| JZJ(P)2H150-8 | ZJ(P)150 | 2H15 | 2x10-2 | 150 | 100 | 32 | 3 | 2.2 |

| JZJ(P)2H150-5 | ZJ(P)150 | 2H30 | 2x10-2 | 150 | 100 | 50 | 3 | 4 |

| JZJ(P)2H300-8 | ZJ(P)300 | 2H30 | 2x10-2 | 300 | 150 | 50 | 4 | 4 |

| JZJ(P)2H300-4 | ZJ(P)300 | 2H70 | 2x10-2 | 300 | 150 | 76 | 4 | 7.5 |

| JZJ(P)2H600-8 | ZJ(P)600 | 2H70 | 2x10-2 | 600 | 200 | 76 | 7.5 | 7.5 |

| JZJ(P)2H600-6 | ZJ(P)600 | 2H100 | 2x10-2 | 600 | 200 | 80 | 7.5 | 11 |

雙羅茨單滑閥真空機(jī)組主要性能參數(shù)表

| 機(jī)組型號(hào) | 泵型號(hào) | 極限壓力 | 抽氣速率 | 進(jìn)氣口徑 | 排氣口徑 | 電機(jī)功率 | ||||

| 主泵 | 中間泵 | 前級(jí)泵 | Pa | L/s | mm | mm | Kw | |||

| JZJ(P)H300-43 | ZJ(P)300 | ZJ(P)70 | H25 | 2x10-2 | 300 | 150 | 40 | 4 | 1.5 | 2.2 |

| JZJ(P)H600-43 | ZJ(P)600 | ZJ(P)150 | H50 | 2x10-2 | 600 | 200 | 50 | 7.5 | 3 | 5.5 |

| JZJ(P)H600-42 | ZJ(P)600 | ZJ(P)150 | H70 | 2x10-2 | 600 | 200 | 76 | 7.5 | 3 | 7.5 |

| JZJ(P)H600-41 | ZJ(P)600 | ZJ(P)150 | H150 | 2x10-2 | 600 | 200 | 80 | 7.5 | 3 | 15 |

| JZJ(P)H600-24 | ZJ(P)600 | ZJ(P)300 | H70 | 2x10-2 | 600 | 200 | 76 | 7.5 | 4 | 7.5 |

| JZJ(P)H1200-44 | ZJ(P)1200 | ZJ(P)300 | H70 | 2x10-2 | 1200 | 250 | 76 | 11 | 4 | 7.5 |

| JZJ(P)H1200-43 | ZJ(P)1200 | ZJ(P)300 | H100 | 2x10-2 | 1200 | 250 | 80 | 11 | 4 | 7.5 |

| JZJ(P)H1200-42 | ZJ(P)1200 | ZJ(P)300 | H150 | 2x10-2 | 1200 | 250 | 80 | 11 | 4 | 15 |

| JZJ(P)H1200-24 | ZJ(P)1200 | ZJ(P)600 | H150 | 2x10-2 | 1200 | 250 | 80 | 11 | 7.5 | 15 |

| JZJ(P)H2500-44 | ZJ(P)2500 | ZJ(P)600 | H150 | 2x10-2 | 2500 | 320 | 80 | 22 | 7.5 | 15 |

雙羅茨雙級(jí)滑閥真空機(jī)組主要性能參數(shù)表

| 機(jī)組型號(hào) | 泵型號(hào) | 極限壓力 | 抽氣速率 | 進(jìn)氣口徑 | 排氣口徑 | 電機(jī)功率 | ||||

| 主泵 | 中間泵 | 前級(jí)泵 | Pa | L/s | mm | mm | Kw | |||

| JZJ(P)2H300-45 | ZJ(P)300 | ZJ(P)70 | 2H15 | 1x10-2 | 300 | 150 | 32 | 4 | 1.5 | 2.2 |

| JZJ(P)2H300-42 | ZJ(P)300 | ZJ(P)70 | 2H30 | 1x10-2 | 300 | 150 | 50 | 4 | 1.5 | 4 |

| JZJ(P)2H600-42 | ZJ(P)600 | ZJ(P)150 | 2H70 | 1x10-2 | 600 | 200 | 76 | 7.5 | 3 | 7.5 |

| JZJ(P)2H1200-44 | ZJ(P)12600 | ZJ(P)300 | 2H70 | 1x10-2 | 1200 | 250 | 76 | 11 | 4 | 7.5 |

| JZJ(P)2H1200-43 | ZJ(P)1200 | ZJ(P)300 | 2H100 | 1x10-2 | 1200 | 250 | 80 | 11 | 4 | 11 |