Series 2YK liquid ring vacuum pumps own the features of high vacuum and better applicability. When suitable actuating medium or sometimes pumped medium can be chosen as actuating liquids, the series pumps almost can pump all industrial gases. Aforesaid pumps own the features of reposefully operation, low noise and less than 30 percent of energy consumption compared with water vapour jet vacuum pump. So the liquid ring pumps can be widely used for light, food, medicine, paper making and electric utility industries etc.

There are projects as follow for consumer to choose

1.AThere are projects as follow for consumer to choose ccording as the degree of vacuum

●If the pump is operated for long time with the inlet pressure ranging between 1.3×104Pa and 1×105Pa(between 100 and 760 Torr). Please choose series SK water ring vacuum pump.

●If the pump is operated for long time with the inlet pressure ranging between 5×103Pa and 1.3×104Pa(between 40 and 100 Torr). Please choose series 2SK water ring vacuum pump.

●If the pump is operated for long time with the inlet pressure ranging between 1×103Pa and 5×103Pa(between 8 and 40 Torr). Please choose series 2YK liquid ring vacuum pump.

2.Working liquid

●The water with normal temperature. The temperature of supply water range best from 5℃ to 20℃. The highest temperature of supply water should be not higher than 40℃.

●Transformer oil or industrial oil with low viscosity and saturation vapour pressure. The highest suitable temperature of the oil should be not higher than 60℃, for example electric utility industry: Vacuum drying.

●Chemical liquid, choose direct the chemical raw material with low saturation vapour pressure, for example ethylamine etc.

●Besides the water with normal temperature, if choose other working liquid, should equip separator and radiator etc. the dynamic seal of the shaft should use the mechanical sealing. Detailed performances see the list.

3.Choose the dynamic seal of the shaft:

●Choose the asbestos coil when the pump is used in the generic occasion.

●Choose the mechanical sealing when the pump is used in no leak occasion.

4.Choose the material of the part that the gas passed.:

●Besides the shaft, other parts are made of cast iron or alloy of copper; it is suitable for pumping no corrosive gas.

●Stainless steel 304 and 306, it is suitable for pumping corrosive gas.

●Engineering-oriented plastic, it is suitable for pumping acidic and corrosive gas.

5.If the pump is used for pump gas and transport gas. The pressure of gas outlet port exceeds atmosphere pressure. We choose the pump according as something as follow:

●If the pressure of gas outlet port is exceed 0.15Mpa, should choose the especial double-stage liquid ring compressor and should not choose the refitted vacuum pump. The power should be augmented. Should equip the especial separator and auto-drainage.

●If the pressure of gas outlet port is under 0.15Mpa, can choose the refitted vacuum pump as compressor.

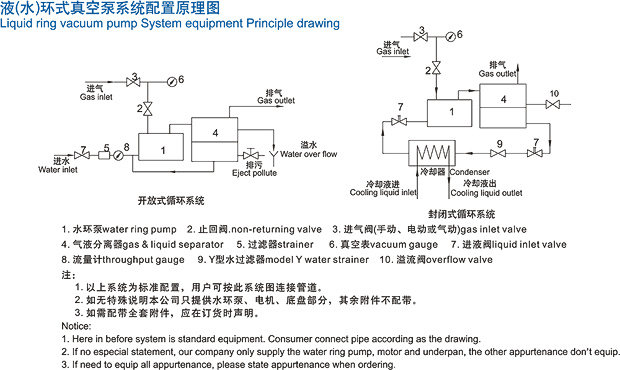

6.Methods of installation water ring vacuum pump system

●When the working liquid of the gas outlet port do not recirculate or part recirculate. Should use the opening circulation system.

●When the working liquid of the gas outlet port must recirculate and not drained off. Should use the closing circulation system.

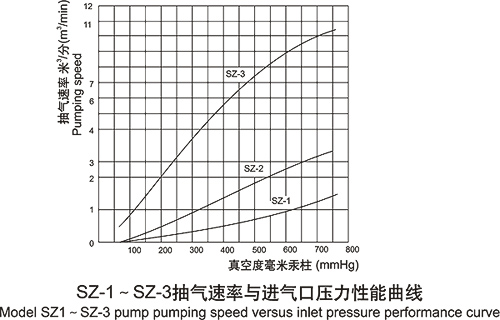

Model SZ pump main performance-parameter table

| Model | Pumping speed | Ultimate pressure | Power | Rotating speed | Water supply | Inlet & outlet dimensions | Weight | |

| m3/min | hPa | Torr | kw | r/min | L/min | mm | kg | |

| SZ-1 | 1.5 | 160 | 122 | 4 | 1450 | 10 | 70 | 140 |

| SZ-2 | 3.4 | 130 | 100 | 7.5 | 1460 | 20 | 70 | 250 |

| SZ-3 | 11.5 | 80 | 60 | 22 | 980 | 70 | 125 | 530 |

| SZB-8 | 0.84 | 150 | 110 | 3 | 1450 | 8 | 1" | 80 |

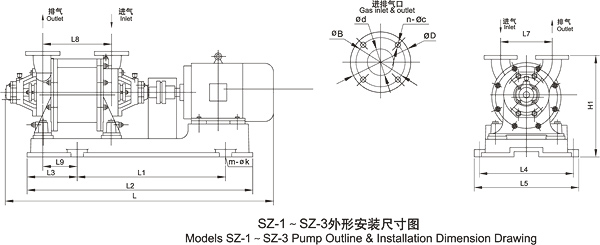

Model SZ-1~SZ-3 pump outline & lnstallation dimension drawing

| Model | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L | H1 | H | D | d | B | n-Øc | m-Øk |

| SZ-1 | 572 | 840 | 168 | 455 | 505 | 635 | 256 | 190 | 95 | 1004 | 490 | 160 | 70 | 130 | 4-Ø14 | 4-Ø18 | |

| SZ-2 | 690 | 1050 | 233 | 455 | 505 | 670 | 256 | 320 | 150 | 1248 | 490 | 490 | 160 | 70 | 130 | 4-Ø14 | 4-Ø18 |

| SZ-3 | 1600 | 1824 | 112 | 640 | 710 | 285 | 215 | 2154 | 765 | 1017 | 235 | 125 | 210 | 8-Ø18 | 4-Ø27 |